Offering top-quality machining services, Wordingham Technologies manufactures critical-to-function custom optics components used within the medical industry. With a strong reputation for producing precision instrumentation, we were contracted by a client located in Germany to construct a thermal block test plate. Possessing over 5,000 individual dimensions, we manufactured this complex component to meet exact client specifications.

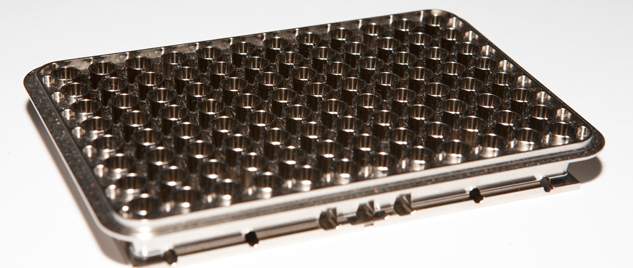

Using our 5-axis, Mori Seiki NV5000 vertical machining center, we machined the plate to measure precisely 4.681″ in overall length, 3.261″ in width, and .560″ in height. Our advanced machine tools allows us to maintain tight tolerances of .002″ for true position and .002″for flatness on this project. Each pocket is parabolic and there are 96 total. The plate was made from 6063-T5 aluminum material and was provided a smooth, 16 RMS electroless nickel finish per AMS 2404 specifications.

Promising worry-free quality, we ensured that each piece met exact design requirements through a series of in process testing, Auto CMM and statistical analysis. Furthermore, all inspection requirements are determined by our quality supervisor and customer print.

Using our advanced CNC milling technology, we were able to successfully construct a thermal block test plate for the medical industry. This complex, precision instrument was ROHS compliant and successfully met all of our customer’s unique design requirements. After manufacturing is complete, we shipped this product directly to our client’s facility in Germany.

(585) 768-2513

(585) 768-2513