At Syntec, we vertically integrate mold and tooling development with your total needs for design, production and assembly. Innovative designs for unitized molds and inserts let us support you at every phase — from early releases through to the highest volumes — with a minimum of costly rework. We also offer a full spectrum of services including:

- Design and manufacture of entire injection, optical and insert molds

- Tight tolerance non-optical molds for assembly components

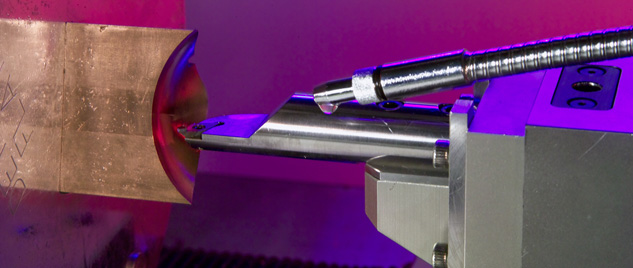

- Single point diamond turning of optics such as mirrors, over-size lenses, collimators, prisms, cylinders, torics, diffractives and grating systems, using polymers or crystals

- HRDT™ (High Refraction Diamond Turning), a unique Syntec process that produces optical quality surfaces on materials that can’t be diamond turned successfully, such as Ultem

In addition to molds for plastic optics that combine refractive and diffractive technologies, Syntec offers conventional mold manufacturing and design services. We use 3-D modeling software, CNC lathes, milling and grinding machines and high precision wire and die sink EDM.

(585) 768-2513

(585) 768-2513