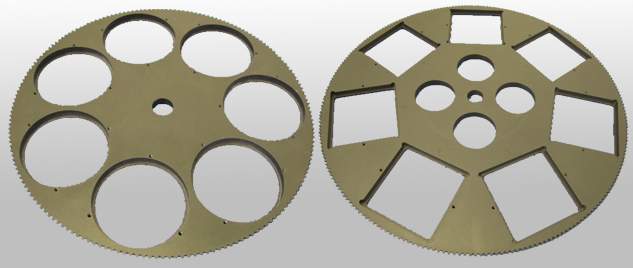

Using our custom machining capabilities and experience, Wordingham Technologies uses CNC milling to manufacture an aluminum filter wheel for a customer in the optics industry. Our MORI Seiki DCG Vertical Mill is used for the CNC milling of the filter wheel itself, as well as for a stainless steel bushing used with the filter wheel. Working within tolerances of ±1° for angles and +.0005″/-.0000″ for linear dimensions, the 6061-T6 aluminum filter wheel has an outside diameter measuring 7″, with 182 total individual teeth CNC milled around the wheel. The stainless steel bushing measures 0.595″ at its outside diameter, and features a scroll thread for glue adhesion.

In addition to these complex features, the filter wheel receives a satin etch black anodize finish (per MIL-A-8625 Type II Class 2), and the wheel must be laser engraved with a 16 pt Arial font number. Finally, the assembly is completed as the bushing is inserted with Loctite.

(585) 768-2513

(585) 768-2513