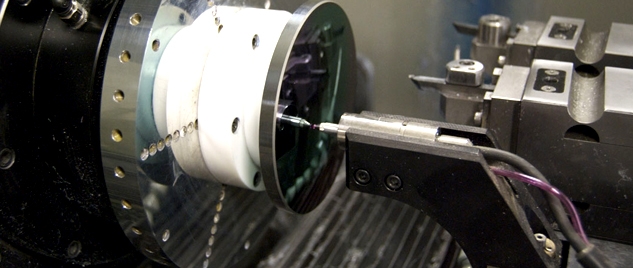

High Refraction Diamond Turning (HRDT) for NIR Applications

Until now, polymers for high index, heat-resistant, NIR optics could only be molded; prototypes required 8–12 weeks minimum, mold costs raised production break-even points.

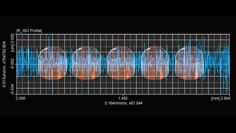

Using advanced optical plastics like Ultem™, HRDT can reliably achieve a surface as smooth as 60 Angstroms, with even smoother surfaces theoretically possible. HRDT, a patented process from Syntec Optics, enables direct diamond turning lowering costs by 2 to 5X:

- Suits spherical, aspherical, toroidal, cylindrical, cone and plano shapes

- Works for lens surfaces with multiple diffractive structures

- Supports polyetherimide and polyethersulfone thermoplastic resins

| POLYMER | ||||

| Time/cost | Glass | Molded | SPDT | HRDT |

| Fast development | Yes | No | Yes | Yes |

| Prod. start-up costs | No | Yes | No | No |

| Vol. prod. cost adv. | No | Yes | No | No |

| Spectrum | ||||

| Visible | Yes | Yes | Yes | Yes |

| NIR | Yes | Yes | No | Yes |

| MWIR/LWIR | Yes | Not Yet* | Not Yet* | Not Yet* |

| * Hybrid solutions are possible | ||||

Discover our patented technology High Refraction Diamond Turning at SyntecOptics.com. From machining Visible Spectrum Optics to NIR Spectrum Optics, we can assist with your project.

(585) 768-2513

(585) 768-2513