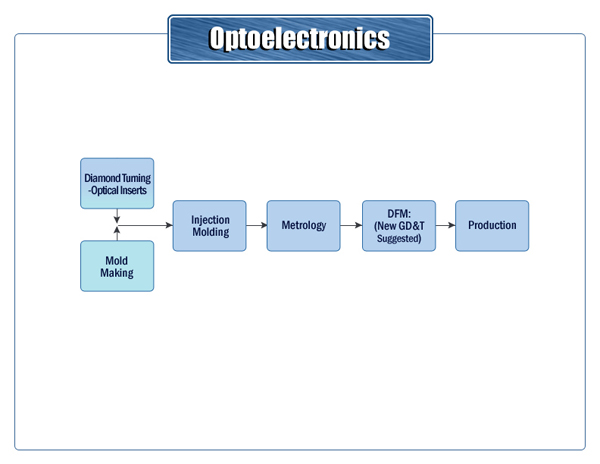

Syntec Optics was commissioned to build a tool for a prism which would be used in an optoelectronic assembly. During the tool build, our customer decided to change the optical prescriptions of the aspheric surfaces. Such a change can delay the delivery of a tool by weeks. In this case, Syntec was able to provide single point diamond-turned (SPDT) optical inserts made from copper and minimize the impact to the tool delivery. After evaluating our molded samples in their system, the customer happily informed us that the performance equaled that of glass lens prototypes and exceeded their requirements.

With a full understanding of the customer’s requirements, Syntec was also able to (1) suggest a new geometric dimensioning and tolerancing (GD & T) strategy which resulted in more accurate evaluation of critical features and (2) suggest new dimensional tolerances on critical features in order to ensure the part performed to the customer’s expectations.

To learn more about this project, or for more information on our other products and services, please contact Syntec Optics.

(585) 768-2513

(585) 768-2513