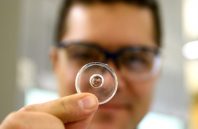

Researchers from Washington State University and Ohio State University have developed a low-cost, easy way to make custom lenses that could help manufacturers avoid the expensive molds required for optical manufacturing.

Led by Lei Li, assistant professor in the School of Mechanical and Materials Engineering, and graduate student, Mojtaba Falahati, the researchers developed a liquid mold from droplets that they can manipulate with magnets to create lenses in a variety of shapes and sizes. Their work is featured on the cover of the journal, Applied Physics Letters.

They first tried to make their own lenses using 3D printing but found it difficult to control the lens shape. They then came up with the idea of using magnets and the surface tension of liquids to literally create free-flowing molds.

(585) 768-2513

(585) 768-2513